| Size: | |

|---|---|

| Availability: | |

| Quantity: | |

OE#41060-40U90/WD0653A000

Private Label, Customized Label

8708301000

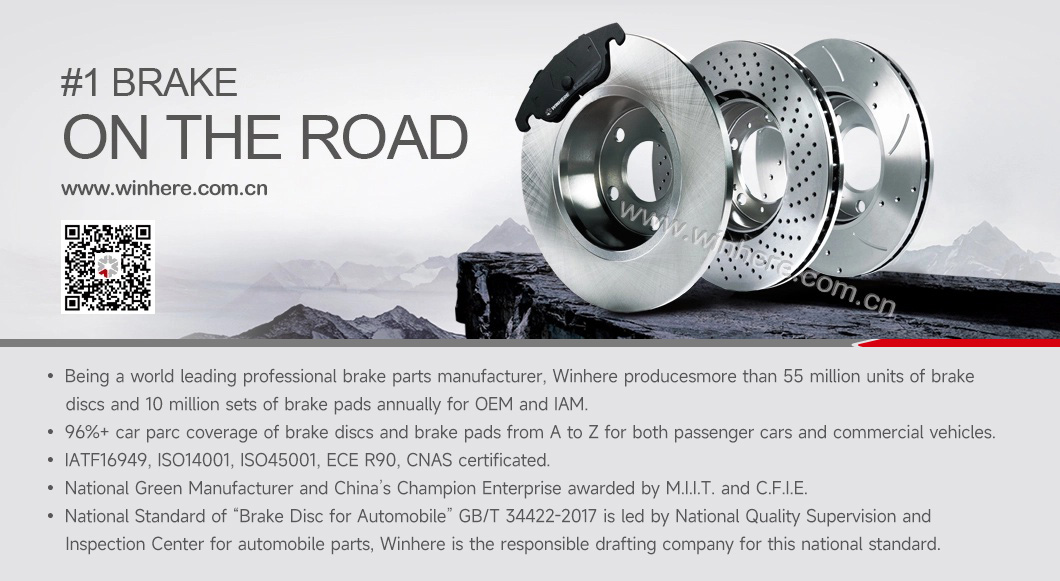

Company Profile

Products

ECE R90-certified dustless brake pads custom-engineered for Nissan front brake systems, precisely tailored for electric and hybrid models including the Sylphy e-Pure, Leaf, and X-Trail e-Power. Manufactured to Nissan's original equipment (OE) technical specifications, the dust-free formula meets the cleanliness requirements of electric vehicles. Installation holes perfectly align with brake calipers for direct fitment without modification. Compatible with ABS/ESP and kinetic energy recovery systems, these pads excel in core scenarios like urban commuting and highway cruising.

Utilizing a low-dust resin-based composite material reinforced with ceramic particles, dust emission is reduced by 80% compared to conventional brake pads, effectively minimizing wheel hub dust accumulation. After high-temperature curing, the friction coefficient stabilizes between 0.38 and 0.42, aligning with the torque characteristics of Nissan electric vehicle motors. This design effectively suppresses thermal fade during continuous braking and precisely coordinates with the kinetic energy recovery system to ensure linear, controllable braking performance.

Engineering details prioritize both durability and quiet operation: The steel backing plate features an electrophoretic anti-corrosion coating to resist moisture-induced corrosion. Laser-engraved grooves on the friction surface rapidly disperse water and residual dust, enhancing stability on wet and slippery road surfaces.

Test and Inspection:

100% critical dimensions, runout and DTV inspection

Material physical and chemical inspection

Test shear strength, compressibility, density, flatness and parallelism

Test performance and noise/NVH

Catalogue

Certifications

Address: No.80, Taishan Road, ETDZ of Yantai , China

Tel: 0086-532-85761111 | Fax: 0086-532-85768370 | Email: autoparts@winhere.com.cn

Copyright © 2020 Winhere Auto-Part Manufacturing Co., Ltd.