| Size: | |

|---|---|

| Availability: | |

| Quantity: | |

OE#424310E070/YH22554

Private Label, Customized Label

8708309990

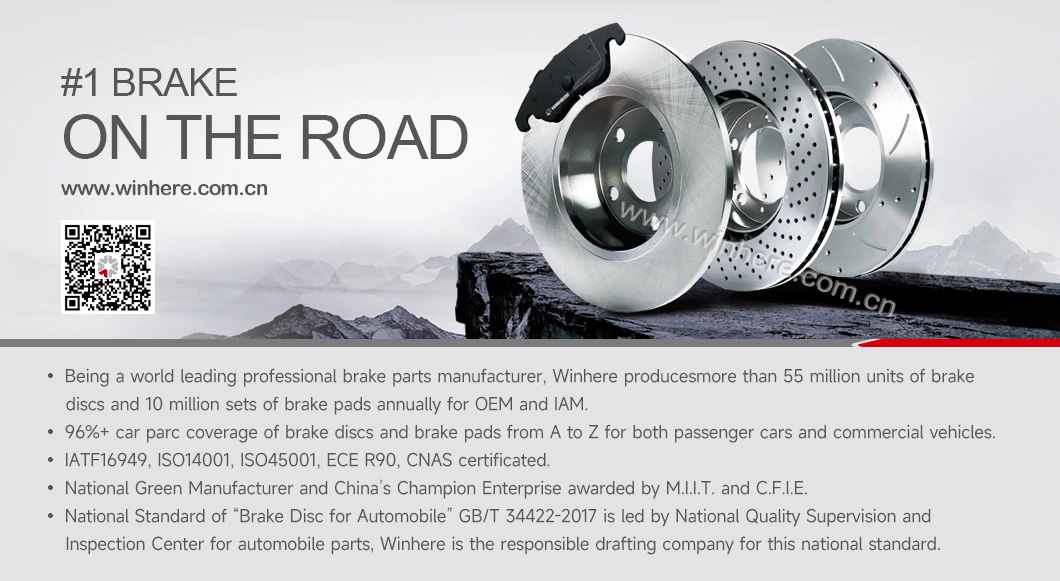

Company Profile

Products

OE-Matched Compatibility: Direct bolt-on fitment for PV models including 308 GTi, 508 SW PSE, and 3008/5008 SUVs. Certified to ECE R90 and IATF 16949, ensuring compliance with EU safety standards and OE interchangeability.

High-Carbon Cast Iron Construction: Premium G3000-grade cast iron friction ring paired with a reinforced steel hub, balancing wear resistance and structural rigidity. Some performance variants feature a floating design (friction ring + aluminum hub connected by steel pins) for enhanced thermal management.

Optimized Groove Patterns: Radial or curved grooves (e.g., Brembo’s "Max" series design) clear debris, expel gases, and improve pad bite. Grooves reduce water buildup during wet conditions, maintaining friction coefficient stability.

Anti-Corrosion Coatings: Zinc-nickel or Geomet coatings pass 1,000+ hour salt spray tests, resisting rust from road salt and moisture. UV-cured finishes (e.g., Brembo’s UV coating) protect against environmental degradation.

NVH Reduction: Non-directional machining and integrated damping shims minimize brake noise (≤35 dB) and vibration, preserving PV’s premium cabin comfort.

Seamless System Integration: Works flawlessly with PV’s ESC, ABS, and regenerative braking (for hybrid models), avoiding "force mismatch" issues. Maintains OE pedal feel and response.

Enhanced Braking Performance: Grooves increase friction coefficient by 15–20% compared to solid discs, reducing stopping distances by up to 5 meters at 100 km/h. Effective thermal dissipation prevents fade during repeated heavy braking (e.g., track days).

Longevity: High-carbon material and corrosion-resistant coatings extend service life by 20–30% vs. standard discs. Reduces replacement frequency and maintenance costs.

Clean & Quiet Operation: Low dust generation (90% reduction vs. semi-metallic pads) keeps alloy wheels clean. Grooves also break up pad glazing, ensuring consistent performance over time.

Safety Across Scenarios: Passes ECE R90 thermal fatigue tests (300°C cyclic heating/cooling) and structural integrity checks (1.5x dynamic load). Reliable in urban traffic, highway driving, and mountainous terrain.

Test and Inspection

100% critical dimensions, runout and DTV inspection

Material physical and chemical inspection

Test shear strength, compressibility, density, flatness and parallelism

Test performance and noise/NVH

Catalogue

Certifications

Address: No.80, Taishan Road, ETDZ of Yantai , China

Tel: 0086-532-85761111 | Fax: 0086-532-85768370 | Email: autoparts@winhere.com.cn

Copyright © 2020 Winhere Auto-Part Manufacturing Co., Ltd.