| Size: | |

|---|---|

| Availability: | |

| Quantity: | |

99735140101;99735140100

Private Label, Customized Label

8708309990

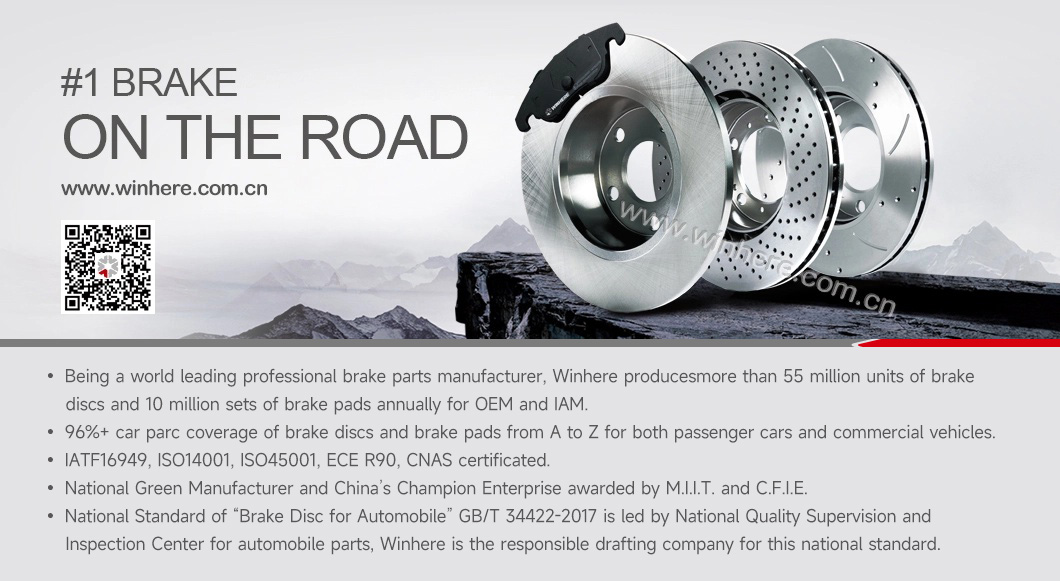

Company Profile

Products

Composite Friction Ring: Constructed from PV composite (phenolic resin + reinforcing fibers) for low weight, high heat resistance, and reduced wear.

Steel/Aluminum Hat: Lightweight hub for structural support, reducing unsprung weight and improving handling.

Optimized ventilation channels and composite material design dissipate heat efficiently, minimizing brake fade during heavy use (e.g., highway braking or track sessions).

Composite material resists rust and corrosion from road salt/moisture, extending service life compared to cast iron discs.

Direct fitment for select vehicle models without modifications, ensuring seamless integration with ABS, ESC, and regenerative braking systems (for EVs).

Composite friction surface reduces brake noise and dust generation, enhancing cabin comfort and environmental friendliness.

Up to 15% lighter than full cast-iron discs, improving acceleration, fuel efficiency, and suspension responsiveness.

ECE R90 certification guarantees compliance with braking performance and structural safety standards.

Longer lifespan and reduced maintenance (e.g., fewer replacements due to corrosion/wear) lower total ownership costs.

Lightweight design aligns with EVs’ energy-saving goals, while heat resistance complements regenerative braking systems.

Stable friction coefficient across wide temperature ranges ensures predictable braking feel in both daily driving and extreme conditions.

Test and Inspection

100% critical dimensions, runout and DTV inspection

Material physical and chemical inspection

Test shear strength, compressibility, density, flatness and parallelism

Test performance and noise/NVH

Catalogue

Certifications

Address: No.80, Taishan Road, ETDZ of Yantai , China

Tel: 0086-532-85761111 | Fax: 0086-532-85768370 | Email: autoparts@winhere.com.cn

Copyright © 2020 Winhere Auto-Part Manufacturing Co., Ltd.