| Size: | |

|---|---|

| Availability: | |

| Quantity: | |

OE#517124E000/CBR2372

Private Label, Customized Label

8708309990

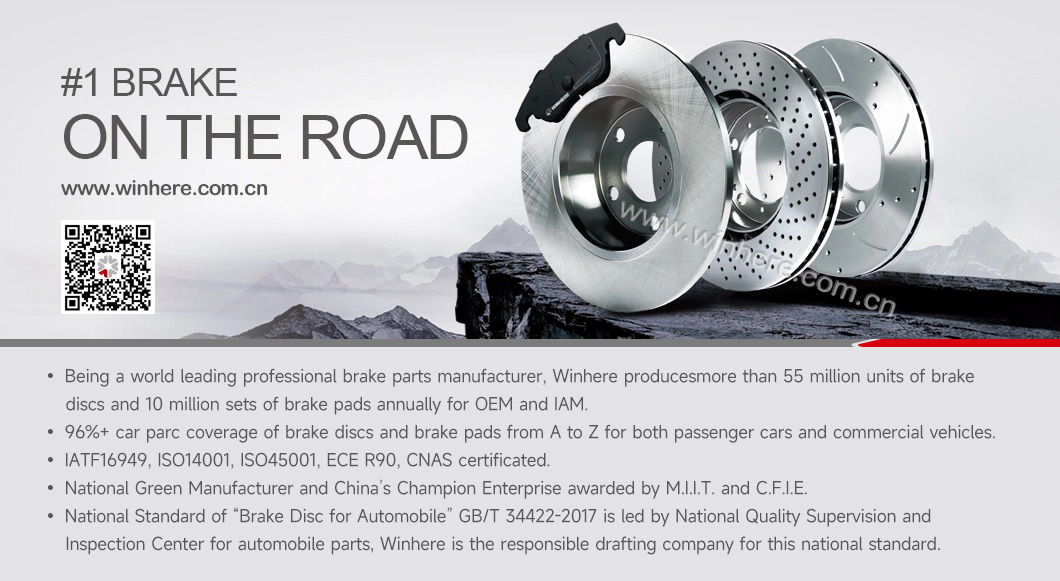

Company Profile

Products

OE-matched for Kia lineups: Fits K5 GT, Sportage, Sorento, and Niro EV; ECE R90/IATF 16949 certified, supporting direct bolt-on installation (no modifications).

Composite structure advantage: High-carbon cast iron friction ring (wear-resistant) + lightweight alloy hat (reduces unsprung weight by ~15%), balancing durability and handling.

Optimized grooved design: 6–8 radial grooves clear brake dust, rainwater, and gas buildup; maintains stable friction even in wet or heavy-braking conditions.

Anti-corrosion protection: Zinc-nickel or Geomet coating on the hat and friction ring edges, passing salt spray tests to resist road salt and moisture.

NVH optimization: Non-directional friction surface + damping shims minimize braking noise and vibration, preserving cabin comfort for family use.

Seamless Kia system compatibility: Works with ESC and hybrid regenerative braking, keeping the factory braking feel and avoiding "force mismatch" during emergency stops.

All-scenario braking stability: Grooves prevent fade in K5 GT’s sporty driving; composite durability handles Sorento’s heavy loads (full cargo + towing).

Extended service life: Wear-resistant cast iron + anti-corrosion coating reduce replacement frequency by ~25% vs. standard discs, lowering maintenance costs.

Quiet & clean experience: Low noise suits family rides; minimal dust keeps Kia’s alloy wheels tidy (critical for Sportage/Niro’s sleek design).

Improved daily handling: Lightweight composite structure enhances steering responsiveness, making city driving (e.g., Sportage) more agile.

Test and Inspection

100% critical dimensions, runout and DTV inspection

Material physical and chemical inspection

Test shear strength, compressibility, density, flatness and parallelism

Test performance and noise/NVH

Catalogue

Certifications

Address: No.80, Taishan Road, ETDZ of Yantai , China

Tel: 0086-532-85761111 | Fax: 0086-532-85768370 | Email: autoparts@winhere.com.cn

Copyright © 2020 Winhere Auto-Part Manufacturing Co., Ltd.