| Size: | |

|---|---|

| Availability: | |

| Quantity: | |

OE#4243142080/YH22696

Private Label, Customized Label

8708309990

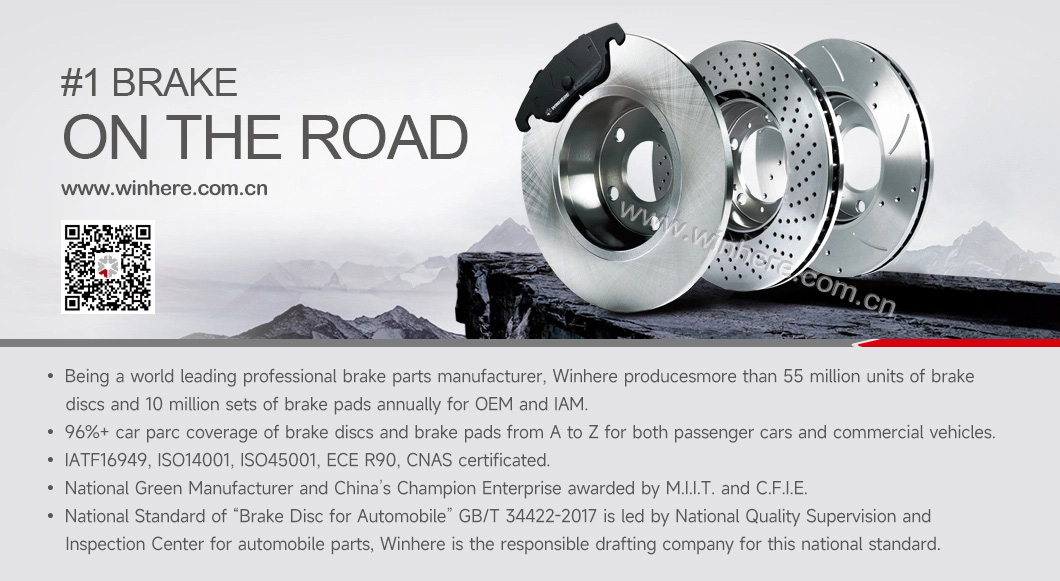

Company Profile

Products

Precision-engineered by Chinese manufacturers, these Jeep high-performance premium brake discs are custom-developed for off-road and urban high-performance scenarios, precisely fitting mainstream models including Wrangler, Grand Cherokee, Compass, and Cherokee. Developed to strict Jeep OEM high-performance specifications, these discs feature installation holes and dimensions perfectly matched to brake calipers for direct, modification-free fitment. Compatible with ABS/ESP and off-road terrain brake assist systems, they handle diverse scenarios including mountain off-roading, extreme driving, and urban commuting.

Constructed from HT300 high-strength gray cast iron infused with molybdenum for reinforcement, these discs undergo precision casting and heat treatment. Their triple-vented hollow chamber design significantly enhances heat dissipation compared to standard discs, effectively suppressing thermal fade during continuous off-road braking while maintaining a stable friction coefficient within the high-performance range of 0.40-0.45. The core features a multi-layer ceramic composite anti-rust coating, forming a dense, long-lasting protective layer that offers 50% greater corrosion resistance than standard coatings. This makes it suitable for harsh environments like off-road mud or coastal humidity.

Craftsmanship details highlight premium quality: The rotor body undergoes five-axis CNC precision grinding, with end-face runout controlled within 0.015mm. Combined with high-precision dynamic balancing calibration, brake resonance noise is reduced to below 40 decibels. The friction surface features densified laser-textured processing to rapidly disperse off-road mud and water accumulation, enhancing braking stability on complex terrain. Precise coating-to-friction surface zoning ensures uniform wear, meeting Jeep's high-intensity usage demands while extending service life.

Test and Inspection

100% critical dimensions, runout and DTV inspection

Material physical and chemical inspection

Test shear strength, compressibility, density, flatness and parallelism

Test performance and noise/NVH

Catalogue

Certifications

Address: No.80, Taishan Road, ETDZ of Yantai , China

Tel: 0086-532-85761111 | Fax: 0086-532-85768370 | Email: autoparts@winhere.com.cn

Copyright © 2020 Winhere Auto-Part Manufacturing Co., Ltd.