| Size: | |

|---|---|

| Availability: | |

| Quantity: | |

Dodge Dart 16-13, Fiat 500X 19-16, Jeep Compass 21-17, Jeep Renegade 19-15 OE#68082120AA/YH21430

Private Label, Customized Label

8708309990

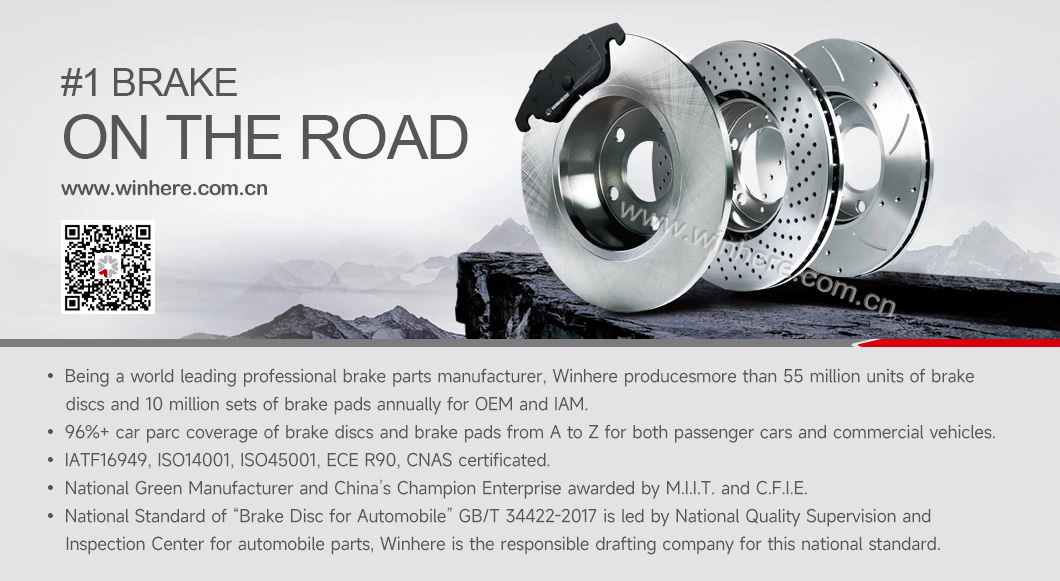

Company Profile

Products

High-carbon brake discs meticulously crafted by Chinese manufacturers to Jeep Heavy-Duty standards. Empowering off-road braking performance with high-carbon material and heavy-duty construction, these discs are custom-engineered for Jeep off-road braking systems. Precisely tailored for mainstream models including Wrangler, Grand Cherokee, Compass, and Cherokee. Developed to strict Jeep OEM specifications, these discs feature perfectly matched mounting holes, locating shoulders, and compatibility with brake calipers and hubs. Installation requires no modifications, and they work seamlessly with Jeep ESP and Off-Road Brake Assist. Ready for mountain trails, extreme crossings, or city commutes.

Hardcore high-carbon material takes performance to the max! Featuring a high-carbon alloy cast iron rotor with an optimal carbon content of 3.4%-3.6%, paired with a heavy-duty structural design. Enhanced by one-piece casting and isothermal quenching processes, the rotor maintains a consistent hardness of 240-280 HBS. Its impact resistance and wear resistance are maximized, perfectly matching Jeep's powerful engine and demanding off-road requirements. Core buffs stacked to the max—high-carbon material + dual-spiral ventilation chambers double disc rigidity. 36 equidistant air channels boost cooling efficiency by 40%, eliminating heat fade during continuous off-road braking. Fade resistance exceeds 35%, with friction coefficient consistently maintained in the golden range of 0.42-0.47. Cathodic electrophoretic anti-corrosion coating ensures rust resistance even after 500 hours of salt spray testing. Tackle muddy off-road trails or coastal humidity with confidence! Core features include a heavy-duty reinforced structure + dual-spiral ventilation chamber design. The rotor body thickness is increased by 15% compared to standard brake discs to enhance load-bearing rigidity. Combined with 36 evenly spaced air channels, heat dissipation efficiency is improved by 40%. During continuous off-road braking, heat fade suppression exceeds 35%, and the friction coefficient remains stable within the high-performance range of 0.42-0.47. Additionally, a cathodic electrophoretic anti-corrosion coating forms a dense protective layer, passing 500 hours of salt spray testing without significant rusting. This makes it suitable for highly corrosive environments such as off-road mud and coastal humidity.

Test and Inspection

100% critical dimensions, runout and DTV inspection

Material physical and chemical inspection

Test shear strength, compressibility, density, flatness and parallelism

Test performance and noise/NVH

Catalogue

Certifications

Address: No.80, Taishan Road, ETDZ of Yantai , China

Tel: 0086-532-85761111 | Fax: 0086-532-85768370 | Email: autoparts@winhere.com.cn

Copyright © 2020 Winhere Auto-Part Manufacturing Co., Ltd.