| Size: | |

|---|---|

| Availability: | |

| Quantity: | |

OE#45251T2FA50;45251T2FA51/YH21548

Private Label, Customized Label

8708309990

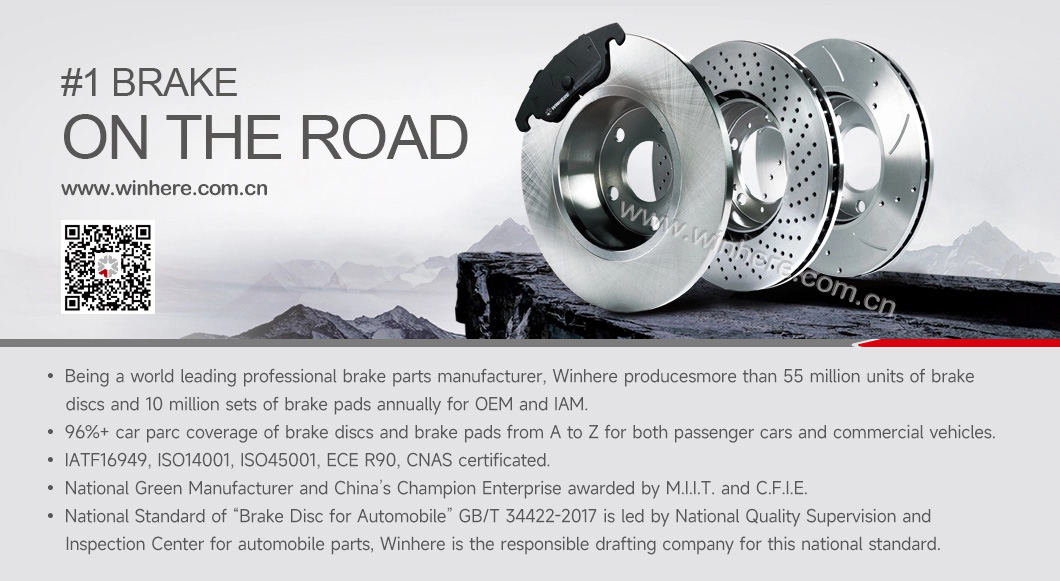

Company Profile

Products

Zinc-Aluminum Coating: Applied to non-friction areas (hub, hat, and vane surfaces) to create a protective barrier against moisture and road salt.

UV-Cured Paint: Some models feature a UV-resistant paint finish on the disc’s outer edges to prevent oxidation.

Environmental Compliance: Coatings meet global standards like ECE R90 and IATF 16949, ensuring safety and eco-friendliness.

High-Carbon Cast Iron: Used in ventilated and solid discs for superior heat dissipation and wear resistance. The carbon-rich alloy (≥0.8% carbon) inherently resists corrosion better than standard gray iron.

Hybrid Composite in Hybrids: Honda’s hybrid models (e.g., CR-V Hybrid) may use composite materials with embedded anti-corrosion additives to balance weight and durability.

Ventilated Core Structure: Front discs often feature a dual-ventilated design to reduce heat buildup, minimizing thermal stress that can accelerate rust formation.

Precision Machining: Smooth friction surfaces reduce debris accumulation, which can trap moisture and cause localized corrosion.

OE Fitment: Directly compatible with Honda’s core lineup, including Civic, Accord, CR-V, and hybrid variants. For example, the CR-V Hybrid’s front discs (289mm diameter) use a zinc-coated, ventilated design optimized for regenerative braking 协同工作.

Braking Efficiency: Retains Honda’s linear pedal feel and ABS/VSA system integration, ensuring consistent stopping power even in wet or salty conditions.

Longevity: Compared to standard OEM discs, anti rust models show up to 30% less surface corrosion after 3 years in coastal environments, according to 第三方测试.

Routine Care: Regular washing and inspection are recommended to remove salt and debris. Avoid harsh chemicals that may damage coatings.

Warranty Coverage: Honda’s factory warranty typically covers rust-related defects for 3 years/36,000 miles, depending on the region.

Test and Inspection

100% critical dimensions, runout and DTV inspection

Material physical and chemical inspection

Test shear strength, compressibility, density, flatness and parallelism

Test performance and noise/NVH

Catalogue

Certifications

Address: No.80, Taishan Road, ETDZ of Yantai , China

Tel: 0086-532-85761111 | Fax: 0086-532-85768370 | Email: autoparts@winhere.com.cn

Copyright © 2020 Winhere Auto-Part Manufacturing Co., Ltd.